In this Article today we will cover about the Bar Bending Schedule [BBS] BBS Step by Step Preparation and Its Advantages | What is Bar Bending Schedule | Advantages of Bar Bending Schedule in Construction | Length of Hook and Total Length of Bar for Different Shapes | Length of Bent Up Bar | Tips for Preparing Bar Bending Schedule | Volume of Steel Reinforcement for Different RCC Members | Bar Bending Schedule Shapes Code

What is Bar Bending Schedule?

Bar Bending Schedule is a detailed list of bent reinforcement bars given in any structural concrete element. Bar Bending Schedule Contains bar mark, Diameter, length, shape, and weight.

The Bar bending is a process of cutting and bending reinforcement steel bar into Desire shape as per structural drawing was given by structural engineer for various structural elements like footing, column, beam, slab, etc.

A Bar Bending Schedule helps site engineer to estimate required quantities of the various diameter of bars used in construction. It helps the engineer to check the reinforcement work done by the contractor.

Advantages of Bar Bending Schedule in Construction.

- Provides better estimation of reinforcement used in each structural concrete member. You can also calculate the overall reinforcement required for the construction project.

- It helps engineer in the procurement of reinforcement steel and better stock management.

- Bar Bending Schedule Provides exact estimated quantity required. So, at a construction site, wastage can be controlled by careful supervising of the contractor with the help of Bar Bending Schedule.

- Bar Bending Schedule makes cutting, bending of reinforcement easy at a factory and can be directly transported to the Construction site. This will not only reduce the wastage of reinforcement steel but also help us reduce labor cost. Though, it helping in reducing the overall cost of the construction project.

- This helps site engineer or quality inspector to check and approve reinforcement work with better quality control.

- Billing can be done really fast and easy using Bar Bending Schedule. It also makes easy for clients to approve bills for Payment.

Step by Step Preparation of Bar Bending Schedule.

First of all, download a Bar Bending Schedule excel sheet by Visiting Below Link to start with the calculation

Step 1: Identification of Members (Steel Bars)

Each different type of Steel bar or Member is usually tagged with a number or bar mark in the structural drawing. Now, open a structural drawing and list down all the shapes of bar you see in the structural drawing. Now mark the diameter of Member in the table.

The above image shows the number of bars like #5, #6, #9, etc, along with Día of the Bar (e.g. #5@12”)

Step 2: Count the Number of bars

Now, Count the number of each different shapes of the bar and note down in bar bending schedule

To calculate a number of bars in big slab structure, you need to check the specific spacing between bars (center to center or c/c, its show in above fig) and the length of the concrete slab in which the bars are distributed.

Number of Bars = (Concrete slab length in which bar is Distributed – 2 X Cover) / (c/c spacing between bars)

For Example:

Suppose, 10 MM bars are distributed in the 10-meter-long slab at 150 mm c/c spacing, Considering the side cover of 50 mm. Then calculate the number of bars

Number of Bars = (10000 – 2 X 50) / (150) = 66 Bars of 10 mm Día

Step 3: Calculate the length of Reinforcement bars

The formula, to calculate the length of those bars.

Length of Bar = Length of Concrete member (direction in which bar is placed) – (2 X Cover) + Development length

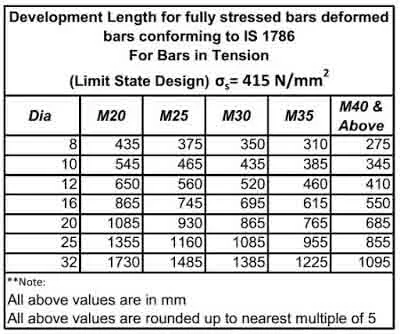

Development Length Chart

Step 4: Calculate the unit weight of Reinforcement Bar

The formula for Calculating Unit weight of Bar

Unit weight of Bar = Volume of Bar X Density of Bar (7850 kg/m3)

Unit Weight of Reinforcement Bar with Día (D) = D2 / 162

Example, 10 mm Día reinforcement bar Weight = 102 /162 = 0.617 kg/m.

However, you can use the below table to check the Unit weight of different Día Bars

| Diameter of Bar (mm) | Unit weight in kg/m |

| 8 | 0.395 |

| 10 | 0.617 |

| 12 | 0.889 |

| 16 | 1.580 |

| 20 | 2.469 |

| 25 | 3.858 |

| 32 | 6.321 |

| 40 | 9.877 |

Step 5: Calculate the Weight of particular Shape of Bar

Wight of Reinforcement Bar (Shape of Bar) = No of Bars X Length of Bars X Unit weight of Bar

This Formula gives the total Weight of specific shape Bar in Kilogram

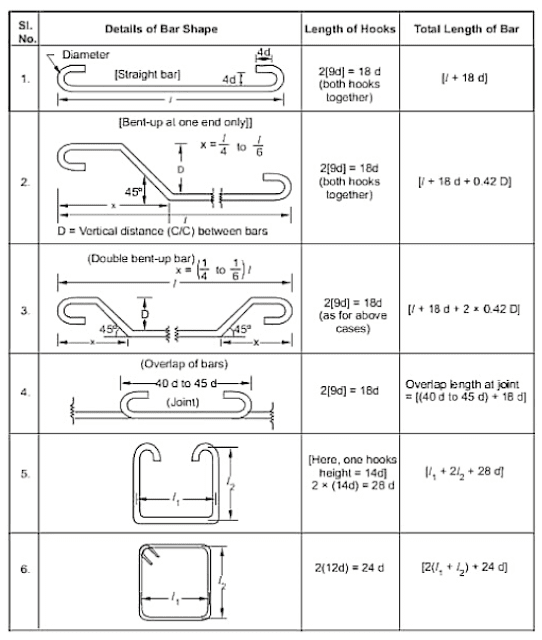

Length of Hook and Total Length of Bar for Different Shapes

List of Common mistake happens during preparing of Bar Bending Schedule

- Miscounting of the Number of reinforcement Bars.

- Calculating the length of reinforcement bar incorrectly

- Considering incorrect cover in Beam, Slab, Column, and footings.

- Incorrect counting of bends in reinforcement Bar.

Tips for Preparing Bar Bending Schedule

- Prepare different Bar Bending Schedule for Different RCC elements (i.e. Divide the table into different parts such as Footing, pedestal, Beam, Column, Slab, etc) to avoid mistakes.

- Always keep the unit weight of bars Handy. It helps you prepare Bar Bending Schedule.

- Keep thumb rules in mind or handy, that always helps you in cross-checking your Calculation.

- Such as,

- Approximate quantity of reinforcement steel for small structure varies from 3 to 4 Kg/Sqft of Built-up area.

- Total Volume of Reinforcement steel for the slab is roughly 1.5% to 2% of the volume of Concrete. (Volume of Steel Reinforcement can be calculated as by dividing the weight by density of steel, that is 7850 Kg/M3)

The volume of Steel Reinforcement for Different RRC member

| RCC Member | Volume of Steel by volume of Concrete |

| Slab | 1.5% – 2% |

| Column | 2.5% – 3% |

| Beam | 2.5% – 3% |

For Example, for 10 M3 concrete in Column, considering 2.5% of steel Volume, the column has a 0.25 M3 of steel. Calculate the total weight of steel and steel weight per M3.

Volume of Steel for 10m3 Concrete = 0.25 m3

Wight of Steel Per M3 Concrete = total Volume of steel X Density of Steel (i.e. 7850 Kg/M3)

Weight of steel for 10 M3 concrete = 0.25 X 7850 = 1962.5 Kg.

For 10 m3 Concrete, the total steel required is 1962.5 Kg.

For 1 m3 Concrete, the total Steel required is 196.25 Kg.

- Keep Close eye on Rolling Margin (weight higher than standard weight)

How to Calculate Rolling Margin of Reinforcement Steel Bar

Cut reinforcement bar into 3 pieces, each length 1 meter

Weight Each piece differently

i.e. 10 mm Día Bar, 1st one weigh 0.617, 2nd one weighs 0.62, 3rd one weigh 0.625

Now Calculate the rolling margin of Reinforcement bar

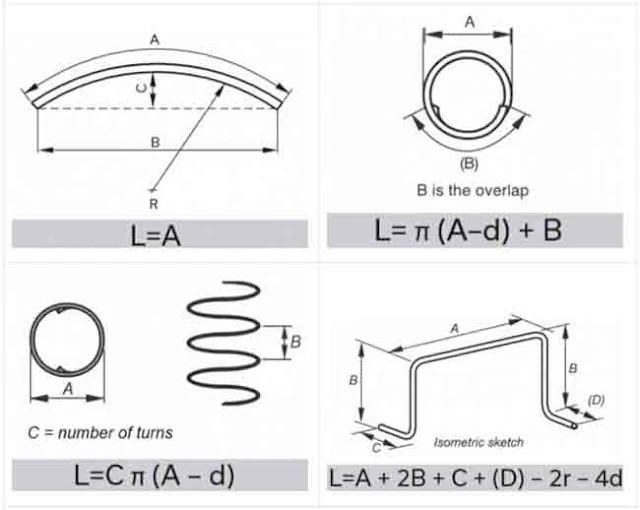

Bar Bending Schedule Shape Code

For Small Construction Project, we generally use thumb rules for Reinforcement bar Calculation, but for Large scale construction project BBS is prepared using Bar Bending Shape Code.

Which helps to avoid unnecessary wastage. Bar bending shape code makes easier for Engineer to cut steel bar for the reinforcement as per the design.

Bar Bending Shape Code as per BS 8666:2005

Different types of Bar Bending Shape Code listed below

Where L stands for Total Length of the reinforcement bar

Minimum Scheduling Radius, Diameter, and Bend Allowance

Minimum Scheduling Radius, Diameter, and Bend Allowance

| Nominal Size of Bar, dia in MM | Minimum Radius for scheduling r | The minimum diameter of Bending former | General (5d straight), including links, where bend is ≥ 150° mm | Links where bend ≤ 150° (Min 10d straight) mm |

| 6 | 12 | 24 | 110* | 110* |

| 8 | 16 | 32 | 115* | 115* |

| 10 | 20 | 40 | 120* | 130 |

| 12 | 24 | 48 | 125* | 160 |

| 16 | 32 | 64 | 130 | 210 |

| 20 | 70 | 140 | 190 | 290 |

| 25 | 87 | 175 | 240 | 365 |

| 32 | 112 | 224 | 305 | 465 |

| 40 | 140 | 280 | 380 | 580 |

| 50 | 175 | 350 | 475 | 725 |

What is Bar Bending Schedule?

Bar Bending Schedule is a detailed list of bent reinforcement bars given in any structural concrete element. Bar Bending Schedule Contains bar mark, Diameter, length, shape, and weight.

General guidelines to be followed in preparing BBS:

- The bars should be grouped together for each structural unit, e.g. beam, column, etc.

- In a building structure, the bars should be listed floor by floor

- For cutting and bending purposes schedules should be provided as separate A4 sheets and not as part of the detailed reinforcement drawings.

- The form of bar and fabric schedule and the shapes of bar used should be in accordance with BS 8666.

- It is preferable that bars should be listed in the schedule in numerical order.

- It is essential that the bar mark reference on the label attached to a bundle of bars refers uniquely to a particular group or set of bars of defined length, size, shape and type used on the job.

- This is imperative as a bar mark reference can then point to a class of bar characteristics. Also, this helps steel fixers and laborers keep track of the type and number of bars needed to complete a certain work.

Conclusion:

Full article on Bar Bending Schedule [BBS] BBS Step by Step Preparation and Its Advantages | What is Bar Bending Schedule | Advantages of Bar Bending Schedule in Construction | Length of Hook and Total Length of Bar for Different Shapes | Length of Bent Up Bar | Tips for Preparing Bar Bending Schedule | Volume of Steel Reinforcement for Different RCC Members | Bar Bending Schedule Shapes Code. Thank you for the full reading of this article in "QA QC Civil Engineering" platform in English. If you find this post helpful, then help others by sharing it on social media.

Full article on Bar Bending Schedule [BBS] BBS Step by Step Preparation and Its Advantages | What is Bar Bending Schedule | Advantages of Bar Bending Schedule in Construction | Length of Hook and Total Length of Bar for Different Shapes | Length of Bent Up Bar | Tips for Preparing Bar Bending Schedule | Volume of Steel Reinforcement for Different RCC Members | Bar Bending Schedule Shapes Code. Thank you for the full reading of this article in "QA QC Civil Engineering" platform in English. If you find this post helpful, then help others by sharing it on social media.

![Bar Bending Schedule [BBS] BBS Step by Step Preparation and Its Advantages Beam,BBS,BBS Slab,Bar Bending Schedule,Costing and Estimation,Civil Engineering,Civil Engineering Basic Knowledge,Civil Engineering Information,](https://blogger.googleusercontent.com/img/a/AVvXsEhT1x5TE054FPy-1I-28IW_QvZ0SiikCJpmF_iuUaNVkttICgaP1PBohc00SMbYhgW9eKgmZ29spXL_WWctKgQiKG7Z0eKbn7kwZoSM0pWMbuBL4-tzQkT3TQDE623Sk3sarSOaAitkyEBj2wUsuL9hGbKxtbanXTKVDE0OPXRAY97G6yq-FLvNOPaG=w640-h360-rw)